Graphite & Carbon Materials- Design, Processing, Assembly

With over 25 years of industry experience, we have built a strong foundation in the manufacturing and application of isostatic graphite, high-purity graphite, carbon-carbon composites, graphite felt,etc. Our expertise extends beyond materials to complete end-use solutions, supporting clients across more than 30 countries and 20 industries—including photovoltaics, optical fiber, semiconductors, energy/Thermal Management, float glass, and vacuum systems.

Guided by continuous innovation and a commitment to quality, SHJ-CARBON delivers high-performance, cost-effective graphite solutions tailored to the evolving needs of global industries. From material selection to final application, we provide one-stop technical support and customized services to promise performance, efficiency, and long-term value.

-

30

Countries

-

25+

Years Experience

-

300+

Clients

-

20

Industries

Precision Graphite & Carbon Materials Solutions

-

Isostatic Graphite

99.99% purity, isotropic structure

Exceptional thermal & electrical conductivity

Ideal for ultra-clean, high-precision applications

Learn More -

Carbon-Carbon Composites (C/C)

2000°C+ thermal stability

Lightweight, high strength

Tailored for aerospace, industrial thermal systems

Learn More -

Graphite Felts

Customizable density and thickness

Low thermal conductivity, chemical inertness

Available in soft & rigid forms

Learn More

Graphite & Carbon Market Solutions for Key Industrial Sectors

-

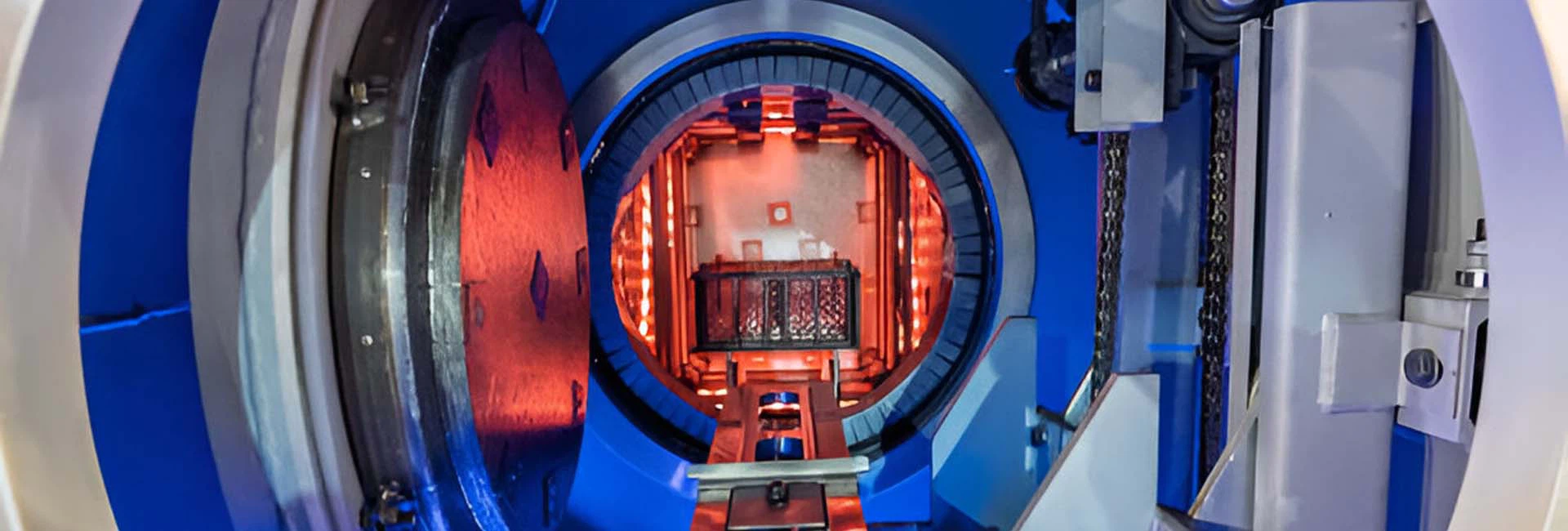

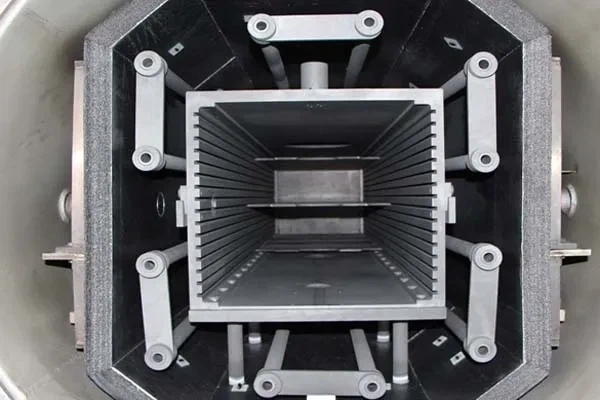

Vacuum Heat Treatment

High-Performance Graphite & CFC for Extreme Thermal Stability

-

Metallurgy

Precision Graphite for High-Stress Metal Processing

-

Energy

Durable Graphite for Energy-Efficient Furnaces

-

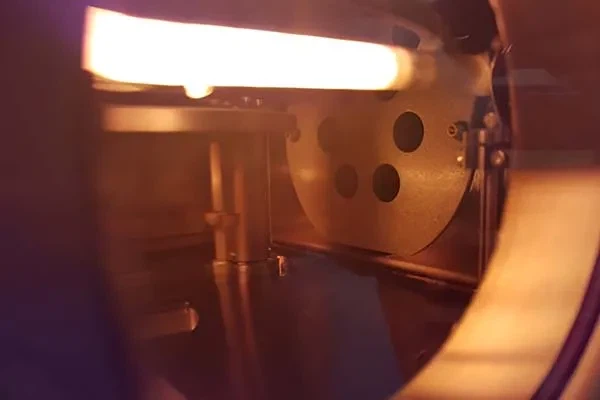

Semiconductor& Fiber Optic

Ultra-Pure Graphite for Semiconductor Applications

-

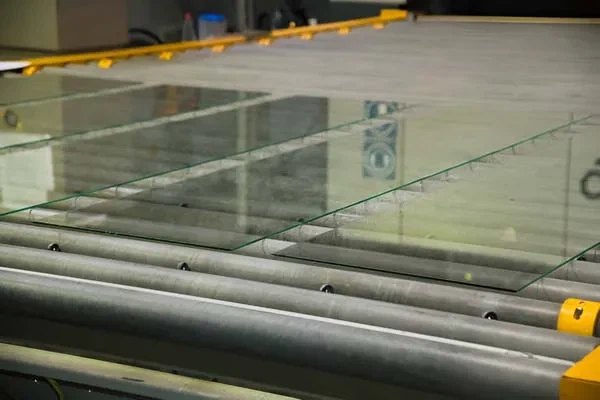

Glass & Ceramics

High-Tolerance Graphite for Precision Glass Forming

-

Other Industrial Application

Providing optimized implementation plans

Custom Graphite & Carbon Materilas Soultion Process

Industrial Graphite & Carbon Solutions — Engineered to Perform

-

Consultation

Precision Engineering Needs Assessment

graphite consultation, custom graphite & CFC project

01

-

Material Solution

Optimized Grade Selection Protocol

Special graphite selection, material compatibility

02

-

Prototyping & Testing

Performance-Validated Pre-Production

graphite product prototyping, performance validation

03

-

Precision Machining & Processing

Advanced Graphite Fabrication Systems

graphite machining, batch processing, C/C composite manufacturing

04

-

Protective Packaging & Delivery

Industry-Specific Transport Solutions

graphite product packaging, safe transport, export-ready delivery

05

Reliable Graphite Components

SHJ-CARBON provides custom graphite products designed for demanding industries, offering durability, cost-effectiveness, and consistent performance to meet your project in sectors like semiconductors and Metallurgy,Vacuum & Heat Treatment and etc.

-

Quick delivery

Various logistics modes are available

-

Free sample

Products sample are availabel

-

Secure Policy

100% secure Policy

-

24/7 Support

Dedicated support

Customized One-Stop Graphite & CFC Solution

At SHJ-CARBON, we go beyond material supply. Our one-stop, fully customized service model is designed to support long-term partnerships with manufacturers in high-temperature industries. From initial material consulting to final component delivery, we focus on precision, purity, and performance—ensuring consistent, trustworthy, and scalable solutions for your production needs.

-

Thermal Field Design

We provide tailored thermal field layout services to enhance uniformity, efficiency, and mechanical stability. Our team works closely with you to optimize designs for vacuum furnaces, crystal growth setups, and powder metallurgy systems—ensuring materials perform reliably under extreme thermal stress.

-

Precision Graphite Machining

SHJ-CARBON delivers high-precision graphite parts specifically for industrial use. Our advanced CNC machining systems handle complex geometries while maintaining tight tolerances and smooth surfaces. From structural elements to fixtures, each component is made to fit demanding process environments with minimal deviation.

-

Graphite Purification

Graphite contains trace elements determined by its raw material composition. During production, major impurities are removed in the final stage through graphitization—a thermal treatment conducted at 2600°C to 3000°C. This transforms baked carbon into electrographite. SHJ-CARBON's purification process reduces impurity levels to as low as 5ppm, ensuring material purity for critical manufacturing.

A Long-Term Partner in Graphite Solutions, Built for Real-World Demands

With over 25 years of industry service, SHJ-CARBON has earned the trust of manufacturers worldwide—not just as a supplier, but as a dependable solution partner. We understand the real pressures of high-temperature manufacturing: tight tolerances, thermal cycling, downtime risks, and the need for absolute reliability.

That's why we go beyond material supply. From early-stage material consultation and selection, to in-house machining, performance validation, and secure packaging—we deliver a full-process graphite solution that helps you simplify procurement, reduce uncertainty, and focus on what matters most: consistent output.

Every graphite component we produce—whether a custom crucible, a heat shield, or a complex C/C composite—is backed by engineering insight, application experience, and a support team that stays with you beyond delivery.

pgrading production lines, preparing for a rebuild, or optimizing thermal systems, SHJ-CARBON is here to support you—at every step—with proven materials, precision manufacturing, and practical industry understanding.

Insights From SHJ-CARBON

-

What Is a Graphite Solution and Why Modern Industries Need It?

What Is a Graphite Solution and Why Modern Industries Need It?Introduction The term graphite solution has become common across industries that d

view more -

What is Isostatic Graphite?

What is Isostatic Graphite?Isostatic Graphite Isostatic graphite is a type of fine-grained graphite used for

view more -

What Is a Graphite Liner?

What Is a Graphite Liner?Introduction Many industrial systems run in environments that involve high heat, c

view more -

CFC vs Graphite Bolts: Which Fastener Performs Better in High-Temperature Fur...

CFC vs Graphite Bolts: Which Fastener Performs Better in High-Temperature Fur...Introduction Engineers often compare CFC bolts and graphite bolts when they select

view more